Our milled Zircozon range of products have been developed for ceramic, refractory, glass, and foundry industries.

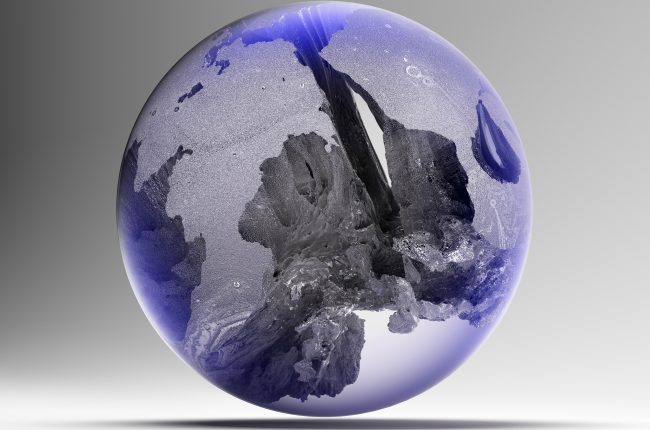

Zircon

We offer a range of materials for use as foundry mould/core sands, glass colourants and high friction surface materials

Foundry Sands

We offer contract milling, calcining, and blending services to meet customers own formulation/specification

Customised Products and Contract Processing

We can supply a range of products globally through our network of trusted partners

Resources MaterialsMinchem HMP Ltd is based in Stoke-on-Trent, UK, the heart of the pottery industry. We are a well-established manufacturer and supplier of a range of products based on Zircon, Zirconia, Alumina, and related minerals and raw materials.

Our unique brand of Zircon Opacifiers, Zircozon, are world class materials, accepted in all ceramic manufacturing countries used in the production of tiles and sanitaryware.

We serve diverse markets worldwide in abrasives, ceramics, colours, electrical insulation, foundries, frits, glass, glazes, investment casting, kiln furniture, metal filtration, paints, pigments, refractories, roads, welding electrodes and a host of other technical applications.

We also offer contract processing of various minerals.

As we supply very niche products, we cover a very large range of industries. Some examples are: